Challenge

A remediation system designed by Mundell for a client included an air stripper for the removal of volatile organic compounds (VOC’s) from impacted groundwater. An air stripper works by passing an air stream through impacted water, causing VOC’s present in the water to volatilize into the vapor-phase. The VOC’s are then carried by the air stream out the discharge stack of the air stripper and into the atmosphere. The remediation system would be located in an operating industrial facility and Mundell’s client was concerned that the off gas from the air stripper stack would be an odor nuisance to the employees at the facility. The most prevalent VOC present was Cumene. This was a possibility as the odor threshold (the minimum concentration of a substance in ambient air at which it is detectable by the human nose) for Cumene is relatively low, 0.088 parts per million by volume (ppmv).

Action

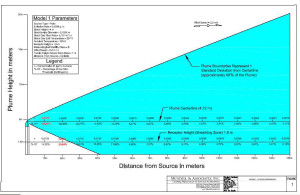

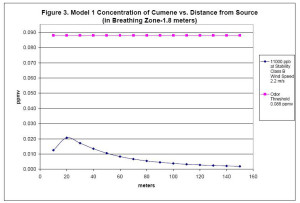

Mundell decided that the best course of action would be to perform an air dispersion model for the air stripper off-gas. Mundell calculated the anticipated “worst case” influent concentration of Cumene in the groundwater entering the air stripper based on the designed flow rate of the water entering the air stripper and by using the highest concentration of Cumene present in any of the designated pumping wells supplying groundwater to the remediation system. These data were used to model the air stripper performance and to determine the concentration (in ppmv) and mass flow rate (in pounds/hour) of Cumene at the air stripper discharge stack. Mundell then used the results of this model and the actual meteorological conditions for the site to perform two air dispersion modes. The air dispersion models characterized how the off-gas plume from the air stripper would behave under the average daytime and nighttime meteorological conditions at the site. The air dispersion models determined how quickly the plume would disperse in relation to the distance it traveled from the air stripper stack and what the concentration of Cumene in ppmv would be at 1.8 meters above the ground surface (the approximate breathing zone for an adult) and at the centerline of the plume at 10 meter intervals along the direction of the plume. MUNDELL analyzed the data from these two models and produced a report which summarized the results.

Results

Mundell’s report showed that even under the “worst case scenario” influent and atmospheric conditions, the resulting off-gas concentrations for the air stripper would remain well below the odor threshold for Cumene. Based on this information the client was able to avoid the use of an off-gas filtration system, resulting in substantial cost savings over the life of the remediation system. The report Mundell provided allowed everyone involved in the project to feel confident in this decision and was suitable documentation for presentation to any associated regulatory agencies if necessary.