Challenge

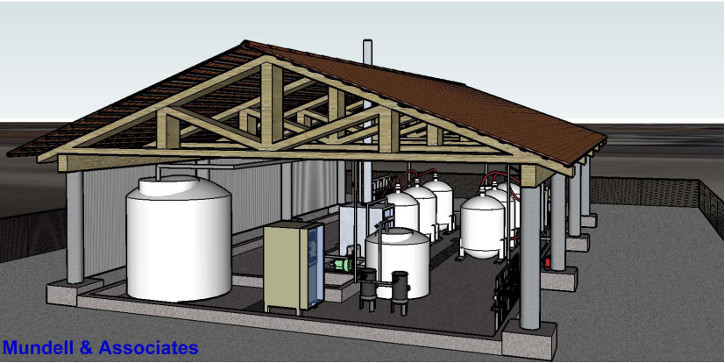

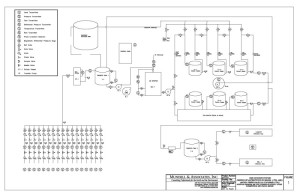

Mundell was asked to design a large scale pump & treat remediation system. This system would need to be capable of treating water from 17 recovery wells with various pumping rates, production volumes, and contaminant types/concentrations. The design of this system would need to ensure maximum production with minimal maintenance time. In addition this system would need to have the capability of being easily adjusted for changing conditions over time.

Action

Mundell explored many different design options for meeting these conditions (one central treatment unit, several independent treatment stations, and individual treatment units for each well). Mundell decided to design one centralized treatment system capable of meeting all the specified requirements. Mundell designed a system that could easily handle and balance the variations in flow from the individual wells. In the interest of keeping maintenance time to a minimum Mundell specified as few mechanical components as possible (for example using pressure transducers instead of traditional float switches to monitor and control water levels in wells and tanks). All routine maintenance operations were accounted for in the design of the system. Mundell designed the system so that these operations could be performed without the need to shut down the system.

Results

Mundell’s resulting design is not only adequate for all of the existing conditions but is flexible and can be easily modified to adjust to changing conditions over time. Because of the forethought that Mundell put into the design, routine maintenance of this system will be very minimal, and will not disrupt system operations.